| 1740 Technical Specifications | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||

All specifications subject to change without notice.

Flexible and Secure |

TOP |

The Model 1740 builds on a long-standing foundation of flexible, powerful test software for the manufacturing environment. In addition to standard tests, optional tests include double insulated Hipot and Polarity. Our unique modular software approach allows the addition of standard options and custom tests or applications upon initial delivery or at any time following installation. This accommodates changing demands and requirements by building on an existing platform rather than replacing software each time change is necessary.

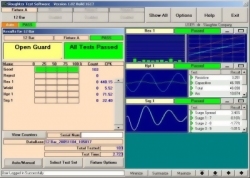

Both automated and manual applications benefit from the flexibility of up to four test stations and the enhanced interface capabilities of the Model 1740. Intuitive displays and indicators minimize error and maximize throughput by simplifying operator notification. A full range of user selectable inputs and outputs allow seamless integration into any automated environment.

Data management has never been easier with multi-level password protection to ensure the security and integrity of test parameters and data. Built-in utilities allow local/network backup and retrieval of setup and configuration data with the push of a button. All test results are available in both numeric and graphic format and are stored in standard Microsoft database format, allowing easy access from external spreadsheet and database applications.

Software |

TOP |

The 1740 Software is a Windows based program that offers a core set of tests including hipot, resistance and surge. The software provides a graphical user interface including intuitive displays and easy-to-read graphic and numeric presentations of data. All tests feature automatic setup of test parameters and storage of all test results. Built-in diagnostics expedite troubleshooting should problems arise. Optional test modules and utilities may be “plugged in” at any time.

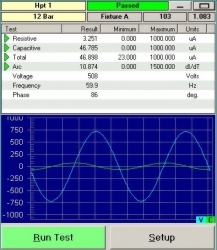

Both AC and DC voltages are available for hipot testing. All tests include upper and lower leakage limits as well as programmable arc detection. The ac test measures capacitive, resistive and total leakage current and can reject based on any of the three. A double insulated hipot test is available for armatures requiring tests from commutator-to-stack, stack-to-shaft and commutator-to-shaft. Graphic displays of both voltage and current are available for all tests.

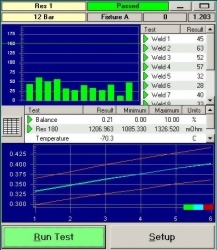

Two resistance test methods are available, one for armatures and one for other products. The armature resistance test provides both bar-to-bar and 180-degree measurements as well as individual tang-weld measurements. This patented measurement technique provides unbeatable speed and resolution. For other products including stators and coils, a standard DC Resistance test is used. Ambient and product temperature compensation are available. All resistance tests include upper and lower limits for complete quality control.

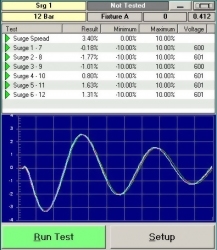

The need to verify insulation integrity makes surge testing one of the most comprehensive single tests available for wound products. This test detects winding problems such as turn-to-turn shorts, coil-to-coil shorts, winding-to-winding shorts and phase-to-phase shorts. The surge test can also detect changes in inductance due to variations in the windings or core material. Digitized analysis allows detection of a single shorted turn for many products.

Hardware |

TOP |

Standard hardware includes computer, instrumentation and switching modules housed in rugged, 19-inch rack-mountable cabinets. Status and signal indicators for each module combine with software to provide unbeatable system diagnostics. Several packaging options including standard industrial racks and workstations are available, or modules can be installed as desired by the end user. This flexibility will handle all installations, even when space is at a premium.

Whether you are troubleshooting problems or performing routine periodic maintenance, Model 1740 hardware is designed with serviceability in mind. Each module is slide mounted, allowing convenient pullout access. Even the most rugged relay may eventually need to be replaced, so switching matrix relay cards can be swapped from the front panel with no tools, minimizing service downtime.

Our modular hardware and software provide the scalability and flexibility to handle a wide variety of applications. Each hardware module features color coded connectors and cabling are to minimize connection error.